Packaging films often do more work than people realize. They seal in freshness, protect against damage, and shape how a product looks and feels long before it’s opened.

Think of a food brand trying to keep chips crisp, or an electronics maker needing a tamper-evident wrap that deters moisture. When the film isn’t suited to the product, quality slips, shelf life shortens, and customers notice. As material science evolves, brands now have smarter, lighter, and more eco-friendly film options that reduce waste and improve overall performance.

This guide breaks down 10 of the best packaging films for 2026, what they’re made for, when to use them, and how they help your product stand out while staying protected.

Key Takeaways

Choosing the right film preserves product quality, extends shelf life, and prevents customer complaints or returns.

Material, barrier, and flexibility must match the product type and environmental conditions for optimal protection.

Films influence branding: clarity, gloss, or textures affect shelf appeal and customer perception.

Sustainable options like PLA, cellulose, and mono-material PE reduce environmental impact and meet eco goals.

Multi-layer laminates, metallized, or high-barrier films balance protection, aesthetics, and operational efficiency.

What Are Packaging Films? Relevance in 2026

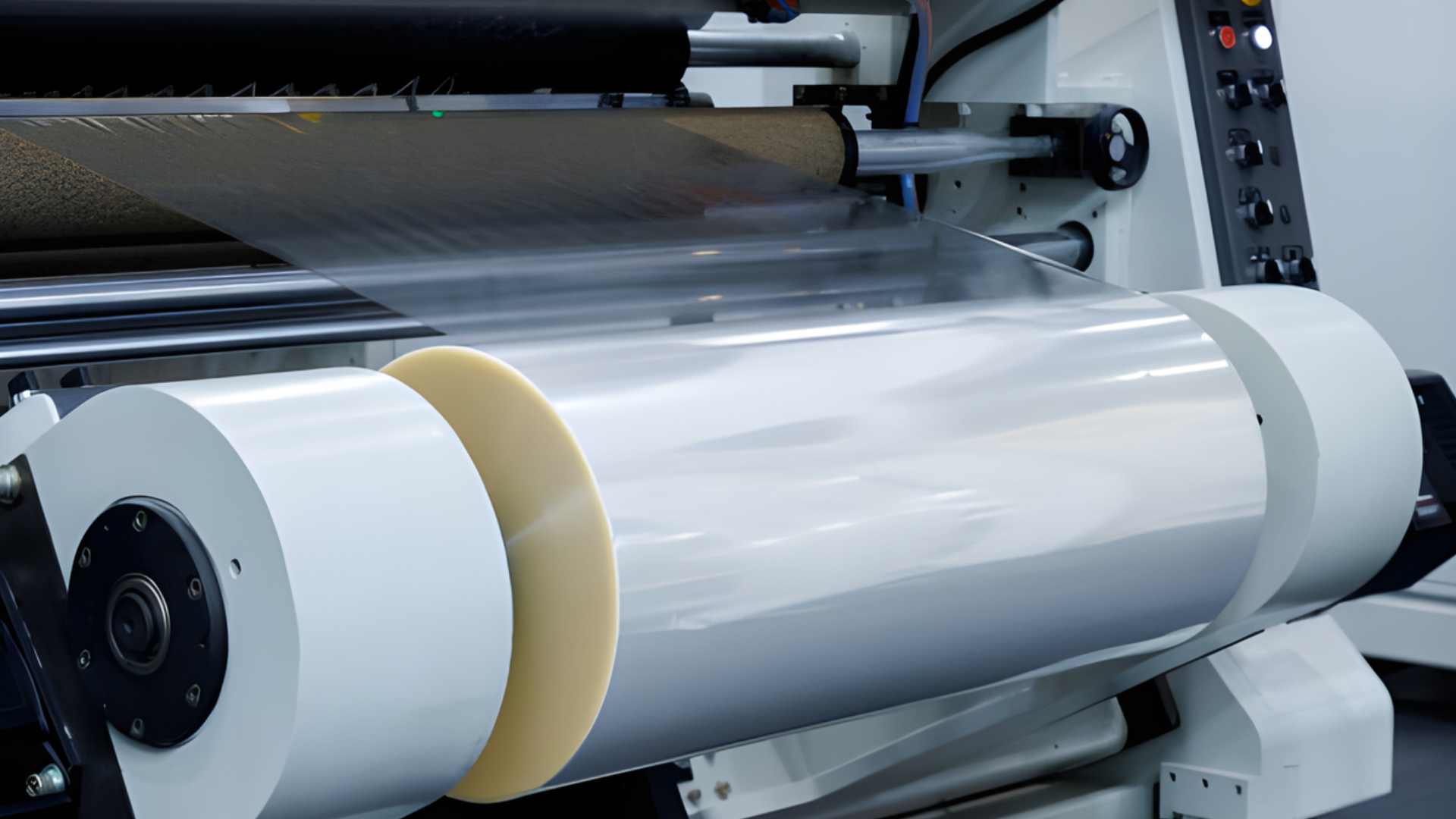

Packaging films are thin, flexible materials made from plastic, paper-based substrates, or biodegradable polymers. Their purpose goes beyond covering or wrapping a product. They protect against oxygen, moisture, dust, UV exposure, and physical damage.

Because they can be transparent, printable, heat-sealable, and customizable in thickness, films are used across food, pharmaceuticals, cosmetics, electronics, and general retail.

In 2026, packaging films matter more than ever as brands look for materials that balance product safety, sustainability, and operational efficiency. E-commerce growth, rising shipping costs, and evolving customer expectations are reshaping how businesses choose and use films.

Here’s why packaging films continue to be essential in 2026:

Lightweight protection: Films reduce overall packaging weight, helping businesses cut shipping costs without compromising durability.

Extended shelf life: High-barrier structures prevent spoilage, oxidation, and contamination, which is crucial for food, supplements, and skincare.

Sustainability pressure: More brands are shifting to recyclable mono-material films, compostable options, and downgauged layers to meet environmental goals.

Improved branding: Modern films allow high-resolution printing, metallic finishes, matte textures, or transparent windows for premium shelf appeal.

E-commerce adaptability: Flexible films perform well in automated packing systems and resist punctures during transit, making them ideal for fast-moving fulfillment.

Choosing the right film in 2026 requires aligning material structure with product needs, including barrier requirements, storage conditions, shelf visibility, sustainability objectives, and filling machine compatibility.

For growing brands, the right packaging film is a tool to enhance product freshness, reduce waste, streamline logistics, and strengthen brand perception in a competitive market.

Also Read: Best Subscription Boxes to Try in 2025

10 Best Packaging Films Brands Can Use in 2026

Picture a snack brand using a low-barrier film for chips: oxygen seeps in, the crunch fades within days, and customers assume the product is stale. Or a cosmetics label wrapping serums in the wrong flexible film: the packaging creases, leaks, or reacts with oils, damaging both the product and brand trust.

Even e-commerce brands feel the impact. Using stiff, non-stretch films for bundling can lead to torn wraps, wasted material, and higher breakage during transport. When brands choose correctly, films extend shelf life, improve sealing efficiency, reduce waste, and elevate product presentation.

Below are the ten most reliable and widely used film types that help brands protect products while enhancing performance and shelf appeal:

1. Polyethylene (PE) Films

Polyethylene films are known for their flexibility, durability, and excellent moisture barrier, making them a go-to choice across food, industrial, and consumer packaging. Their adaptability across LDPE, HDPE, and LLDPE grades allows brands to fine-tune strength, clarity, and stretch based on product needs.

Common subtypes:

LDPE: FDA-approved; used for food wraps, grocery bags, shrink bundling films, and protective sheets.

HDPE: Strong, lightweight, and stiff; ideal for cereal liners, retail bags, and chemical pouches.

LLDPE: Superior stretch and puncture resistance; used for pallet wraps, heavy-duty bags, and flexible liners.

Differentiating factors:

Reliable moisture barrier that keeps food and sensitive products fresh.

Highly flexible structure suitable for high-speed packaging and heat-sealing lines.

Cost-efficient with wide availability, making it scalable for large production runs.

Best for: Food products, frozen items, protective wraps, industrial liners, retail bags, and any application where flexibility, moisture protection, and affordability are priorities.

2. Polypropylene (PP) Films

Polypropylene films are prized for their clarity, gloss, and moisture resistance, making them ideal for visually appealing packaging that travels well. Compatible with high-speed packing lines and heat-sealing processes, PP films help brands maintain product quality while enhancing shelf presentation.

Subtypes:

BOPP (Biaxially Oriented PP): High clarity and printability; used for snack packaging, confectionery, and retail labels.

CPP (Cast PP): Softer and more flexible; ideal for bakery wraps, lamination layers, and garment packaging.

Differentiating factors:

Excellent clarity and gloss that enhance visual appeal on shelves.

High compatibility with heat sealing and automated packaging lines.

Strong moisture barrier to protect sensitive products from humidity.

Best for: Snacks, confectionery, baked goods, apparel packaging, retail labels, laminated films, and any product needing glossy, moisture-resistant packaging with print-ready surfaces.

3. Polyvinyl Chloride (PVC) Films

PVC films provide excellent clarity and a reliable oxygen barrier, making them ideal for protecting products while keeping them visible to consumers. Heat-shrinkable and available in both rigid and flexible forms, they adapt to various packaging needs.

Subtypes:

Rigid PVC: Used for clamshells, trays, and durable packaging.

Flexible PVC: Used for shrink sleeves, wraps, and flexible pouches.

Differentiating factors:

Superior clarity and gloss for premium product presentation.

Effective oxygen and moisture barrier to extend shelf life.

Heat-shrinkable properties allow tight, protective fits around products.

Best for: Pharmaceutical blister packs, shrink-wrapped foods, meat and cheese packaging, clamshell electronics, and any product requiring secure, transparent packaging that highlights contents.

Note: PVC use in food packaging is declining in some markets due to regulatory pressure, so brands should confirm compliance before selecting it.

4. Polyethylene Terephthalate (PET) Films

PET films are known for high tensile strength, thermal stability, chemical resistance, and dimensional accuracy, making them suitable for demanding packaging environments and multilayer applications.

Subtypes:

Biaxially Oriented PET (BoPET): Offers superior clarity, strength, and barrier properties.

Metallized PET (MET-PET): Adds light and oxygen barrier for sensitive products.

Differentiating factors:

Excellent mechanical and thermal properties for heat or microwaveable packaging.

Superior clarity and printability for labels and promotional designs.

Durable in multilayer laminates, enhancing barrier protection for oxygen- or moisture-sensitive items.

Best for: Microwaveable food trays, beverage labels, release liners, high-barrier laminates, premium snack packaging, and multilayer pouches for food, pharmaceuticals, or cosmetics.

5. Polyamide (Nylon) Films

Nylon films offer outstanding puncture and abrasion resistance, excellent oxygen barrier properties, and durability in cold storage, making them ideal for long shelf-life and vacuum-sealed products.

Subtypes:

Cast Nylon Film: Flexible and strong for vacuum packaging and cook-in-bag applications.

Oriented Nylon Film: Enhanced puncture resistance and dimensional stability for frozen goods.

Differentiating factors:

High oxygen barrier protects sensitive foods and extends shelf life.

Puncture and abrasion resistant, ensuring product integrity during handling and transport.

Freezer-safe and suitable for cooking applications without compromising durability.

Best for: Vacuum-sealed foods, frozen meals, meat and seafood packaging, cook-in-bag products, ready-to-eat meals, and long-shelf-life refrigerated goods.

6. EVOH (Ethylene Vinyl Alcohol) Barrier Films

EVOH films are designed for superior oxygen barrier performance, protecting sensitive and perishable products while maintaining freshness and extending shelf life. They are usually combined with moisture-resistant layers like PE or PP for complete protection.

Subtypes:

Co-extruded EVOH Films: Laminated with PE/PP layers for moisture and oxygen protection.

High-Barrier EVOH Sheets: Used in multilayer pouches and trays for long shelf-life products.

Differentiating factors:

Exceptional oxygen barrier: Preserves freshness and prevents spoilage in sensitive foods.

Compatible with multilayer structures: Works with PE/PP layers for moisture resistance and heat sealing.

Extends product shelf life: Ideal for vacuum packaging and long-term storage.

Best for: Baby food pouches, dairy products, shelf-stable meals, vacuum pouches, pharmaceutical packaging, and oxygen-sensitive products requiring extended freshness.

7. Biodegradable & Compostable Films

These are films made from renewable resources such as polylactic acid (PLA), starch blends, or cellulose, offering an eco-friendly alternative to conventional plastics. They break down under industrial composting conditions, reducing environmental impact while maintaining sufficient strength for packaging.

Subtypes:

PLA Films: Clear, strong, and heat-sealable; ideal for retail packaging and food wraps.

Starch-Based Films: Flexible and biodegradable; used for bags and lightweight wraps.

Cellulose Films: Transparent, renewable, and compostable; suitable for confectionery and fresh produce.

Differentiating factors:

Eco-friendly and renewable: Reduces plastic waste and supports sustainability goals.

Adequate strength for light-to-medium packaging: Protects products while being compostable.

Customizable for branding: Can be printed on for attractive, sustainable packaging solutions.

Best for: Organic food packaging, compostable bags, fresh produce wraps, sustainable retail packaging, single-use wraps, and eco-conscious consumer goods.

8. Multi-Layer Laminated Films

Multi-layer laminated films combine two or more materials, such as PET/PE, BOPP/CPP, or Nylon/EVOH/PE, to deliver superior strength, barrier protection, heat resistance, and sealability. Their layered structure allows brands to optimize protection against moisture, oxygen, and mechanical stress while maintaining product visibility and shelf appeal.

Subtypes:

PET/PE: Offers stiffness, clarity, and heat-seal compatibility; ideal for snacks and labels.

BOPP/CPP: High gloss, printability, and moisture barrier; used for confectionery and bakery wraps.

Nylon/EVOH/PE: Provides oxygen and moisture barriers with puncture resistance; suited for vacuum-sealed or long-shelf-life foods.

Differentiating factors:

Enhanced barrier performance: Protects sensitive foods and pharmaceuticals from oxygen, moisture, and contamination.

Multi-material strength: Resistant to tearing, punctures, and heat during processing and storage.

Supports premium packaging: Retains clarity and print quality for branding while offering functional protection.

Best for: Stand-up pouches, retort packs, vacuum-sealed foods, high-barrier snacks, ready-to-eat meals, premium confectionery, and long-shelf-life products.

9. Stretch and Shrink Films

Stretch and shrink films are flexible packaging solutions designed to secure, bundle, and protect products during transport, storage, or retail display. Stretch films cling tightly around pallets or grouped items, while shrink films conform to the product shape when heated, providing a tamper-evident, neat presentation.

Subtypes:

Stretch Film: Elastic, clingable films for pallet wrapping, logistics, and inventory stabilization.

Shrink Film: Heat-shrinkable films for bundling beverages, cosmetics, retail multipacks, or promotional packs.

Differentiating factors:

Superior load stability: Keeps products tightly secured during transit and stacking.

Puncture and tear resistance: Protects against damage while maintaining presentation quality.

Adaptable and versatile: Works for various shapes, weights, and pallet sizes.

Best for: Pallet wrapping, multipack beverages, cosmetics sets, retail bundles, promotional packs, and logistics shipping where secure transport and tidy presentation are critical.

10. Metallized Films

Metallized films, typically PET or BOPP coated with a thin layer of aluminum, provide excellent barrier properties against oxygen, light, and moisture. They enhance shelf life, maintain product freshness, and add a premium metallic appearance that strengthens brand perception.

Subtypes:

Metallized PET: Strong, heat-resistant, and ideal for high-barrier applications.

Metallized BOPP: Flexible, printable, and suited for snack or confectionery packaging.

Differentiating factors:

Superior barrier protection: Guards against oxygen, moisture, and light, extending shelf life.

Premium visual appeal: Shiny metallic finish enhances product presentation and branding.

Compatible with high-speed lines: Supports sealing, printing, and automated packing efficiently.

Best for: Chips, coffee, tea, supplements, premium snacks, ready-to-eat foods, and any packaged product requiring extended freshness with a high-end look.

Also Read: Best Boxes for Moving Vinyl Records

How to Choose the Right Packaging Film? Key Factors

Selecting the right packaging film requires evaluating multiple factors beyond material type. Choosing incorrectly can compromise product safety, shelf life, or visual appeal.

Brands should consider the following in 2026:

1. Product Type: The product determines the film properties required:

Perishables: EVOH or Nylon films provide high oxygen barrier and freshness.

Heavy or sharp-edged items: Nylon or multi-layer laminated films offer puncture resistance and durability.

Fragile or lightweight products: LDPE or BOPP films protect without adding bulk.

2. Environmental Conditions: Storage, transport, and display conditions influence performance:

Freezer storage: Nylon films resist cracking at low temperatures.

Heat-sealing lines: CPP or PET films perform well with high-speed thermal sealing.

High humidity: Layered EVOH or PET laminates protect moisture-sensitive products.

3. Visual Appeal: Film choice affects branding and shelf presence:

Transparency: BOPP or PET films allow product visibility.

Glossy finish: BOPP creates a premium look.

Matte or specialty textures: Specialty PE or laminates provide tactile differentiation.

4. Sustainability Goals: Eco-conscious materials are increasingly important:

Reduce plastic waste: PLA, cellulose-based, or compostable films.

Recyclability: Mono-material PE or PP simplifies recycling and reduces environmental impact.

Packaging Films by Application Category

This table helps brands match packaging films to product applications, ensuring durability, freshness, and an optimal customer experience:

Application | Recommended Film Options |

Snacks | BOPP/CPP, PET/PE laminates |

Frozen foods | Nylon/PE, PET/EVOH/PE |

Pharma blisters | PVC/PVDC, Aclar laminates |

Ready-to-eat meals | Retort laminates (PET/Alu/CPP) |

Bakery & confectionery | BOPP, PE, compostable PLA |

Industrial packaging | HDPE, shrink LDPE, BOPP tapes |

Aligning film type with product, environment, and branding needs maximizes efficiency and enhances customer experience.

Conclusion

In 2026, brands face multiple challenges when selecting packaging films: ensuring product protection, extending shelf life, maintaining visual appeal, meeting sustainability goals, and keeping costs under control. Choosing the wrong film can result in damaged goods, compromised quality, or diminished customer trust.

Alliance Packaging Group helps brands navigate these challenges with a wide array of packaging films tailored to product requirements and operational workflows. From high-barrier laminates and metallized films to eco-friendly biodegradable options, our solutions combine protection, premium presentation, and sustainability to elevate every product experience.

Discover the full range of packaging films at alliancepkggroup.com and see how the right choice can safeguard your products while enhancing customer experience.

FAQs

1. How do I choose between mono-material and multi-layer films in 2026?

Mono-material films are easier to recycle but may offer weaker barriers, while multi-layer laminates can give superior oxygen, moisture, and grease protection. The choice depends on your product’s shelf-life needs and whether you must meet new recyclability or EPR rules in your target markets.

2. Do high-barrier films always mean longer shelf life for my product?

Not always. Shelf life also depends on sealing quality, pack geometry, headspace gas, and how cold the supply chain is. A mid-barrier film with excellent sealing and stable logistics can outperform a high-barrier film used with poor sealing or inconsistent storage.

3. How much does film thickness really matter beyond “stronger vs weaker”?

Thickness affects machinability, seal integrity, puncture resistance, and roll-change frequency. Going too thin can cause line stoppages and micro-leaks; going too thick can trigger higher material taxes, worse recyclability scores, and higher shipping emissions.

4. Can the same film work across flow-wrap, VFFS, and pouch machines?

Some modern films are engineered for multi-line compatibility, but seal-initiation temperature, coefficient of friction, and stiffness still vary by machine type. Always test candidate films on each machine family before standardizing to avoid downtime and sealing issues.

5. How do inks and coatings on films affect recyclability and food safety?

Heavy ink coverage, metallic layers, cold-seal, or specialty coatings can interfere with both recyclability and migration limits in food-contact applications. Manyw brands specify “design-for-recycling” inks, de-metallized barriers, or washable coatings to balance branding, safety, and compliance with emerging packaging regulations.